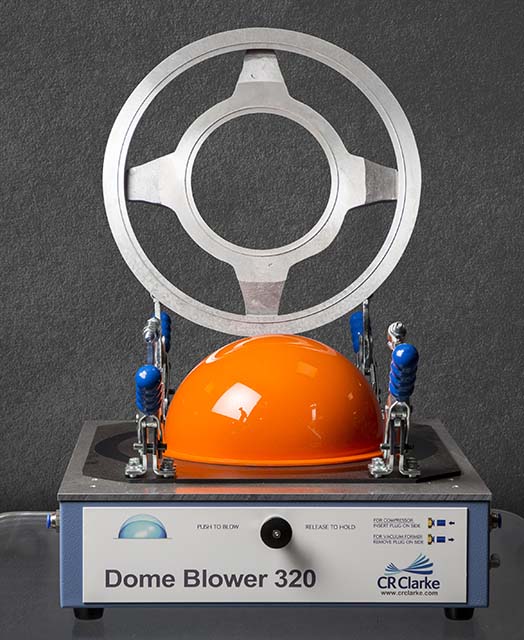

The 650 Dome Blowing Unit consists of a spider base with adjustable clamps, onto which a rigid base is mounted. The base has a heat-proof seal plate that perforations to allow air to be injected. A sheet of thermoplastic material, normally cast acrylic, is heated in an oven to its softening temperature. The material is transferred to the Dome Blowing Unit and is clamped into position. Air is blown under the sheet using the control valve on the front panel, inflating the dome. Once cooled, the dome is unclamped and is immediately ready to use.

The 650 can be fitted with ring and base plate combinations to create any size of dome up to 600mm in diameter.

The unit is mounted on a stand with lockable castors, for ease of location in the workshop. The 650 requires an external compressed air supply.