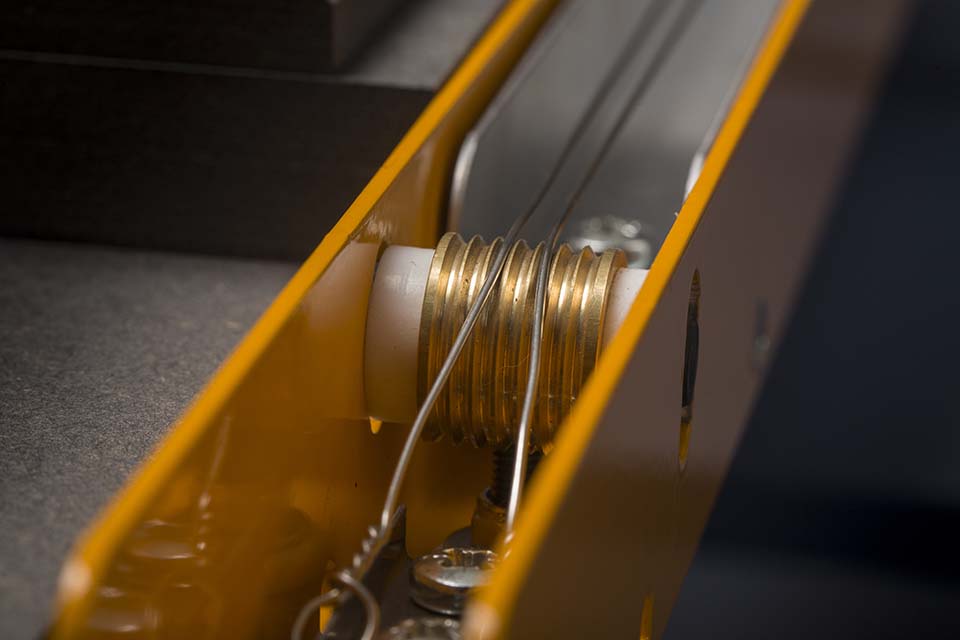

Heater beams are only 30mm wide, allowing close-centre bends to be produced with ease. Heater beams are fitted with twin wires for fast heating of materials up to 6mm in thickness. Calibrated adjustments ensure easy and repeatable setup. Different combinations of wire spacings, heights and wire power can be used to produce the best results on most materials.

Heater Beams are powered from low-voltage Power Packs with variable power control. This enables heating wires to be adjusted to exactly the required output for the material being processed. We use one Power Pack per heater beam so that each beam can be adjusted or isolated individually, for maximum flexibility. For multi-beam machines on stands, we offer a power distribution centre in either 16 or 32 Amp capacity, neatly splitting the power coming into the machine to the individual Power Packs.

The Support Slats on the F…S range are made from high grade fibre board, ensuring that they are long-lasting and gentle on the material being processed. Support slats are securely fastened in place and can be easily moved as required. The front support slat also incorporates the workstop, and this is positioned to allow the side calibrations to be used for both stops and heater beams for ease of setup.

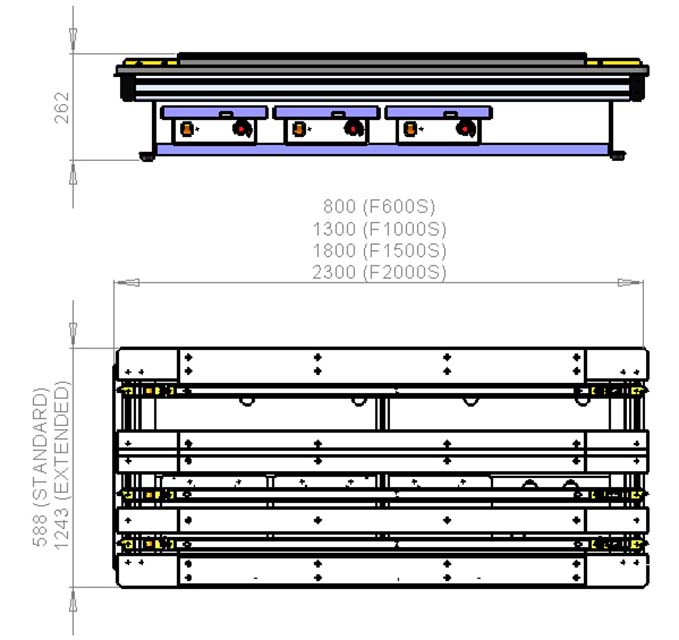

Voltage

Max Current

Maximum Working Length

Maximum Material Thickness

Dimensions (Packed)

Weight (max)

230V 50-60Hz

4 Amps

600mm

6mm

815 x 588 x 262mm

40kg

Voltage

Max Current

Maximum Working Length

Maximum Material Thickness

Dimensions (Packed)

Weight (max)

230V 50-60Hz

6Amps

1000mm

6mm

1315x 588 x 262mm

55kg

Voltage

Max Current

Maximum Working Length

Maximum Material Thickness

Dimensions (Packed)

Weight (max)

230V 50-60Hz

8Amps

1500mm

6mm

1815x 588 x 262mm

70kg

Voltage

Max Current

Maximum Working Length

Maximum Material Thickness

Dimensions (Packed)

Weight (max)

230V 50-60Hz

12 Amps

2000mm

6mm

2315 x 588 x 262mm

90kg