Voltage

Max Current

Sheet Size

Maximum Material Thickness

Maximum Mould Height

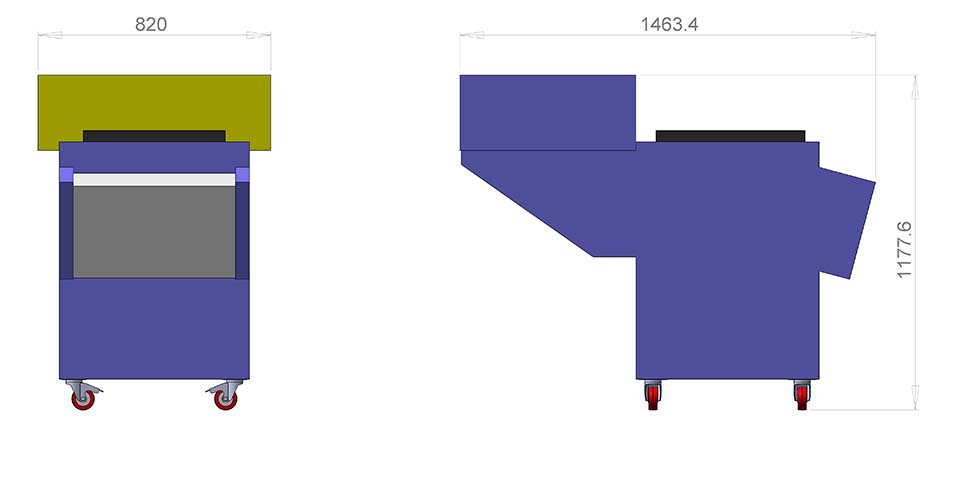

Dimensions (Packed)

Weight

230 50-60Hz

15 Amps

508 x 458mm

6mm

305mm

800 x 1400 x 900mm

152kg

1820R/1. Reducing Plate to accept half the standard sheet size, 458 x 254mm.

1820R/2. Reducing Plate to accept quarter the standard sheet size, 254 x 228mm.

1820R/S. Reducing Plate manufactured to the customers required sheet size.

1820MD. Material Roll Dispenser, allowing the machine to be fed by a roll of material.

1820CF. Material Cooling Fans with delay timer.